Liquid-Solid separation

From lab to pilot and full production scale,

De Dietrich Process Systems filtration solutions are highly versatile and adaptable to many chemical processes (pharmaceuticals, chemicals, natural extraction, precious metals, dyes...)

De Dietrich Process Systems filtration solutions are highly versatile and adaptable to many chemical processes (pharmaceuticals, chemicals, natural extraction, precious metals, dyes...)

Description

Our team of process experts work with you to define your requirement, evaluate feasibility, proceed through small scale trials and scale-up calculations.

From the smallest company to the largest system, from the simplest machine to the most complicated, we are here to help you define your needs.

Filter-dryers can be used for the following batch process steps:

- Filtration (formation of the cake)

- Cake smoothing

- Cake washing (piston- or reslurry washing)

- Vacuum drying

- Cooling

- Automated discharge

With over 2000 filter-dryers in operation, sold successively under the brands De Dietrich Process Systems and Rosenmund-Guedu, we are a world leader in all types of Nutsche filter liquid-solid separation with sizes ranging from 0.01 to 16m² and an unmatched material range,

- Manual or automated Nutsche filters

- Filter dryers from pilot to production scale

- Glass, glass lined, stainless steel, hastelloy versions available

Products

Products for solid - liquid separation are:

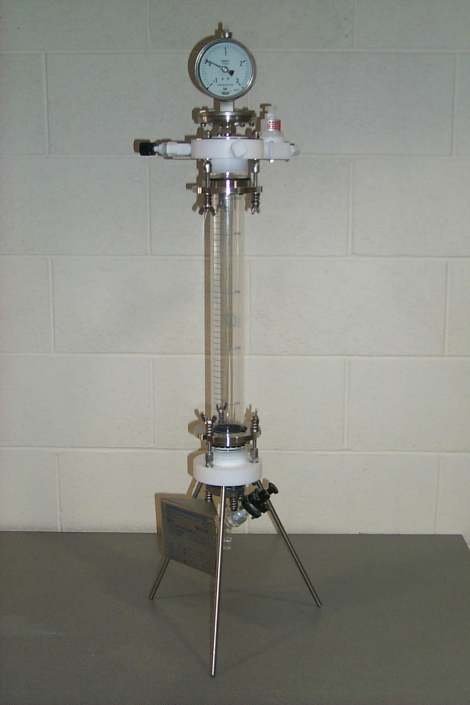

- Pocket filters (made of glass or stainless steel)

- Static Nutsche filters

- Pilot scale filter-dryers

- Industrial scale filter-dryers

Questions? We are here to help.

If you'd like to talk with a sales representative about purchasing De Dietrich Process Systems's products and services, you can reach us here.

Contact us Documents